Intelligent Design Approach for Vacuum Suction Cup Units

Vacuum Suction Cup Units

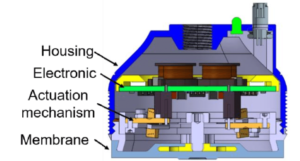

The Smart Suction Cup is designed with a brushless Turnigy motor that generates vacuum inside the suction cup. It features an intelligent microcontroller (PRO TRINKET) that identifies and adapts the signals for its six engines. This system also features sensor information on the legs that help it measure its holding power. The result is a highly effective, lightweight, and flexible vacuum suction unit.

The vacuum suction cups design can address the limitations of the device by changing the gel material geometry and thickness. By using a 3D printer to print the turbine stator, suction cup shapes can be adjusted to better conform to curved or rough surfaces. The grooves can also be adjusted to distribute positive internal pressures and improve grip firmness. Some suction cup designs may include a long thin sticky edge to aid the initial sealing stage, while others may have long and wide sticky edges for easier detachment from flexible surfaces.

The Vuototecnica vacuum work surface uses suction cups and a ball valve to create a vacuum. When the panel is resting on the suction cup, the ball valve will activate a partial-vacuum that will hold the panel to the surface. The ball valve in the suction cup works by pressing against the load of the panels, which activates the valve sealing ball, which creates a partial vacuum and keeps the panels attached to the surface.

Intelligent Design Approach for Vacuum Suction Cup Units

The infrared sensor detects the distance to the support surface and a plane. The model TCRT5000 uses this technology to support glass panes. The infrared sensor detects the vacuum produced by the suction cup. The barometric sensor measures atmospheric pressure and verifies the vacuum performed. All sensors are welded into the integrated circuit for added protection. A linear regulator ensures that all sensors have the same power voltage.

Compared to conventional suction cups, the Intelligent Design Approach for Vacuum Suction-Cup Units is more efficient and robust. This device has a higher suction-force than its counterpart. As the vacuum pressure increases, the cup’s overall grip force will increase. The NF-VSU can withstand a range of temperature conditions. With these features, the NF-VSU is the ideal choice for many surgical applications.

The cup’s shape should be optimized for the application to reduce the adverse effects of deformation on the suction area. To minimise the adverse effects of deformation on the grip surface, the cup should be shorter than the product to be gripped. Its thickness should be adjusted to achieve the target surface elasticity and overall gel stiffness. The design should be flexible enough to accommodate various types of surface.