How an Assembled Circuit Board Can Be Customized for Specific Applications

Assembled Circuit Board Can Be Customized

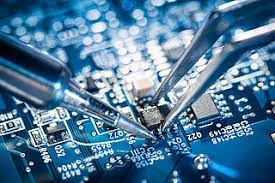

circuit board is a crucial component of any electronic product. It supports the device mechanically and connects all of its electrical components to allow it to function. It also helps to reduce the size of a product, making it possible for it to fit into smaller spaces. These boards are manufactured through a rigorous process that ensures adherence to design specifications and thorough testing. Whether you need a circuit board for an industrial machine or something as simple as a smartwatch, it is important to choose a quality solution that will meet your needs.

A fully assembled circuit board is a complex combination of different types of components, each of which performs a specific function. These include passive components, such as resistors and capacitors, and active components, such as transistors and integrated circuits. The former converts electric power into heat and dissipates it, while the latter switches and controls electrical signals in the board.

It is essential to use high-quality components for your project, as they will be subjected to significant amounts of stress during the assembly and testing process. This stress can cause them to age and become damaged, leading to premature failure. In order to avoid this, it is recommended that you avoid burning your components during the assembly process, and employ proper soldering techniques.

How an Assembled Circuit Board Can Be Customized for Specific Applications

The creation of a custom circuit board begins with a schematic diagram, which is a graphical representation of the board’s components and their connections. After the schematic is complete, it must be turned into a PCB layout. The layout must then be converted into a set of manufacturing files, called Gerber files. These files contain all of the information needed to create a physical board, including the dimensions and locations of drill holes, the copper traces, and the placement of components.

Each of the components on a circuit board must be connected to power and ground planes. These are areas of the board that act as return paths for signals that are routed through traces on the circuit board. If these return paths aren’t properly designed, it can cause problems with the functionality of the circuit board.

To prevent this from happening, it is necessary to pay close attention to the design of the power and ground planes. It is also important to consider the operating temperature range of the circuit board, as active components can generate heat during operation. Additionally, it is necessary to choose components that can withstand the operating voltage and speed requirements of the circuit.

As technology advances, people are demanding tinier, more compact parts. This means that companies who make circuit boards must invest in new materials and methods to keep up with consumer demand. It is also important to focus on sustainability, as this can help to preserve the environment and reduce waste. For this reason, NextPCB is dedicated to using environmentally friendly materials and processes whenever possible. This ensures that their products are as high-quality as possible and provides customers with peace of mind.