What Is Surface Finish For RF PCB?

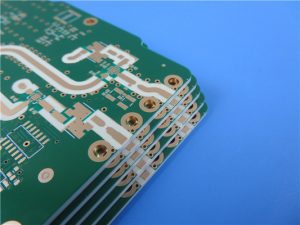

Surface Finish For RF PCB

The surface finish of a PCB plays an important role in the performance, reliability and longevity of electronic devices. This is especially true for RF PCBs, which require special care to ensure proper functionality throughout their intended lifecycle. Understanding the different types of surface finishes available, their properties and how they impact PCB functionality is crucial to choosing the right finish for a specific application. Moreover, proper handling and storage are essential to preserving the quality of PCBs with surface finishes.

During PCB fabrication, the copper layer is often coated with various surface finishes to improve conductivity and solderability. Ideally, the thickness of these finishes is carefully controlled to ensure consistency and optimal performance. However, many factors can influence the quality of these finishes, including temperature, humidity and air quality. These factors can also affect the adherence of the finish to the copper, which can ultimately impact the performance of the finished product. For this reason, ensuring that a finished product is produced in a controlled environment, such as a cleanroom for specific finishes, can help to avoid problems later on.

Some of the most common surface finishes for rf pcb include immersion tin, ENIG and OSP. Each offers unique benefits depending on the intended applications, environment and component type. For example, if the board is intended for use in a high-end or demanding application, an ENIG or ENEPIG finish may be preferred due to their superior durability and longevity. However, these finishes can increase the overall cost of the PCB compared to lower-cost options such as HASL.

What Is Surface Finish For RF PCB?

Another important consideration when selecting a surface finish for RF PCBs is their ability to offer adequate insulation. This can prevent short circuits, electrical leakage and crosstalk between conductive elements on the board. It can also minimize thermal stress that can cause thinning of the copper, which can adversely impact functionality. Fortunately, there are several surface finish options that can provide adequate insulation, such as immersion silver and OSP.

When choosing a surface finish for an RF PCB, it is also critical to consider the budget and production volume. While a higher-end finish like ENIG or ENEPIG may be preferable in terms of performance, it can significantly increase the cost of the board. For this reason, it is imperative to balance the costs of different finishes with the required performance and longevity of the RF PCB.

When deciding on the best surface finish for an RF PCB, remember that proper handling and storage are also essential to preserving its quality. It is recommended that the boards are stored in a dry, cool and dark place to protect them from oxidation and contamination. Additionally, it is recommended that workers wear gloves when handling PCBs with surface finishes, as human skin contains oils and salts that can contaminate the finish and reduce its functionality. Using a lint-free cotton or nitrile glove can help to prevent this contaminant transfer. Finally, storing the RF PCBs in an opaque container can help to protect them from excessive exposure to UV radiation, which can also damage the surface finish.